|

Cal 40 fix

Illusion has sailed many, many miles since the Honeys repaired the trailing edge of the keel.

Photo Latitude / Archives

© 2009 Latitude 38 Publishing Co., Inc.

Stan Honey is one of the three most admired and respected sailors to ever come out of Northern California, and he and wife Sally Lindsay-Honey are also Cal 40 owners. So when he says he has good news for Liz Clark, who discovered a mysterious leak beneath the engine of her Cal 40 Swell, and all other Cal 40 owners, you can rest assured that he knows what he's talking about.

"Sally's and my Cal 40 Illusion, and many other Cal 40s, have had the same leaking problem that Liz is having with Swell. Fortunately, it's an easy repair that does not require removing the engine. Basically, when the Cal 40s were molded, it wasn't possible for the laminators to get much glass into the really skinny part of the trailing edge of the keel just below the hull and above the propeller shaft log. So the boats sometimes develop a weep there. The fix is pretty easy, but has to be done from outside the boat. For the same reason that the original laminators couldn't do a good job from the inside, it still isn't possible to do a good glass job from the inside.

The solution is to haul the boat and, from the outside, grind away all of the dicey glass work that is on the trailing edge of the keel above the shaft log until you get to solid laminate. Then you get West System epoxy, roving, and mat, and laminate it back up to the original shape using plenty of roving. As I recall, it's only a two- or three-day job, but as it's structural, it would be good to have somebody do it who is good with glass. The fact that Cal 40s have solid, rather than cored, hulls makes it pretty easy."

Propeller tube (Shaft log)

I don’t know if this changed during the production run of Cal-40’s, but mine was made of bronze. For whatever galvanic reason, mine was severely corroded. We first noticed the problem when a hole about 1/16” developed, with a similar-sized stream of water nearly sinking the boat while we’d been away for about two weeks. Our “fix” was to slide a section of rubber hose over the exposed section under the engine, and then securing it with multiple hose clamps. It wasn’t a pretty fix, but it worked OK.

But when we had the engine out last winter for replacement, Doug Grant convinced me to replace the whole tube. (I should have said “hole tube”, as that’s what we found when we got it out…lots of holes. Some the size of a quarter.

The extraction:

Doug Grant made up a "slide hammer". It was a 1/2" stainless rod, Approximately 6' long, and threaded at each end. The rod is inserted in the old tube, and a cap is then screwed on to the inboard end which fits just inside the old tube but also has a top plate that is just a fraction smaller than the outside diameter of the tube. This cap is what ultimately pulls the tube out of the boat. A similar cap is then slid onto the rod and inserted into the outboard end of the tube. This aft-end cap keeps the rod aligned in the center of the tube as it is being "hammered" out.

Next came a heavy brass weight, the "hammer". Doug used a piece of brass, hex in shape, for no apparent reason, and about 8" long, and bored out the center, so that it could slide along the rod. Remember, after it's in place, the rod sticks out the back end of the propeller tube about 3'. The brass weight maybe weighed 15 pounds. At the very back end of the rod, we simply screwed on a washer and two nuts to act as the stopper.

Now the action. Simply start sliding the weight along the rod and slam it into the stopper nuts. Do it hard enough, and the tube will move aft, and out of the boat by maybe 1/8" to 1/4". Do it enough times and the tube will have moved out 1'. At this point, mine stopped. Due to some weakness in the bronze, the inboard end started to mushroom. So, we put some liquid soap on the part that had been exposed at the aft end, and then hammered it back in. We then used a saws-all to cut 2" off of the inboard end of the tube and then started again.

This time it came out much more easily. With each slam on the slide-hammer the tube jumped out another 1/2 inch until it was out nearly 1/2 of its 3' length. The last 1/2 simply slid out.

It was a very satisfying process, especially as one of our highly regarded local boat builders had suggested that we "simply" cut out the entire section of the hull, and then rebuild it.

It was a good boat day.

The “G-10” replacement tube should last a very long time.

In-mast wiring

PVC and Pop-rivets.

The pop-rivet trick is really quite simple.

First decide what path the conduit should take up the side or front of the mast.

Mine on the '40 starts out on the port side at the bottom because that was the most convenient place for the wires to exit, works around to the front for the deck light / steaming light and then finally exits somewhat off to port again for the windex and antenna wires at the top of the mast.

Now, every 3'-4' along this path drill two holes (horizontal to each other if the mast were stepped) the size of the pop-rivet you will be using. I understand that monel rivets are the best.

The conduit (3/4" or 1" pvc) is laid out outside of the mast, the pieces glued together as needed, and marked where each wire should exit. Keeping the wiring simple really helps, such as a combination deck light and steaming light. Using a "fish-tape, the conduit is pre-loaded with tracer-lines for each of the wires emerging from the holes and taped to the mast.

The conduit is then inserted into the mast, and a bent coat-hanger can be used to extract the various tracer lines at the appropriate place on the mast.

Then, to secure the conduit to the mast, insert a bent coat-hanger into one of the pop-rivet holes. Ensnare the conduit, and draw it up next to the other hole. While holding it there, drill into the conduit with that same size drill bit as you used to drill the pairs of holes in the mast. Then insert the pop-rivet, and fasten the conduit to the mast. Repeat this process at each set of holes as you work your way up the mast.

Finally, use the tracer lines to pull your wires up through the mast and out at the appropriate place. Using the tracer lines may save you from accidentally drilling through a wire while installing the conduit.

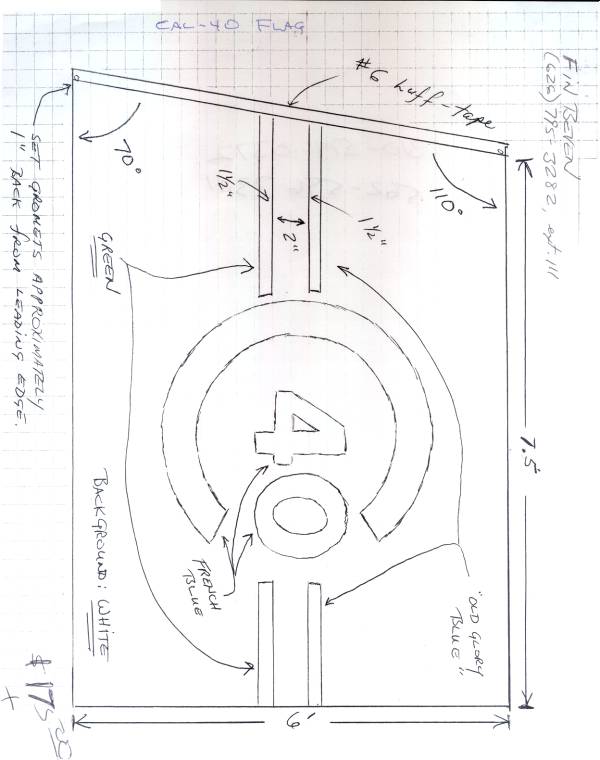

Class Flag

The drawing is for dimension purposes only. All colors can be changed to satisfy the owner's particular tastes.

How to Build a Cal 40 - How to Article. Download Here |